About the Project

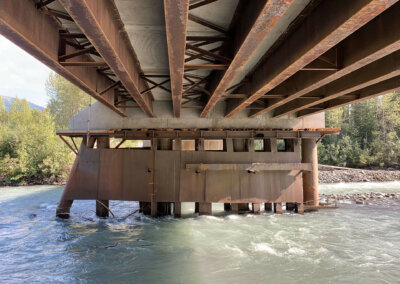

The Taft Creek Bridge on Highway 37, 60 km north of Meziadin Junction, BC, was constructed as a single-lane bridge in 1984. Around 1988, an additional lane was added to make it a 4-span, simply supported, 2-lane steel girder bridge with a timber deck and a length of 68 m. The existing steel girders were showing signs of deterioration, and it was becoming essential to replace the timber with an impermeable concrete deck to protect the steel girders and piles to extend the service life of the bridge.

Pile driving records were incomplete, and based on a desktop study, the piles did not provide enough capacity to support a concrete deck. However, due to the observations of satisfactory bridge performance since construction, the design team proposed an in-situ pile testing program to demonstrate sufficient pile capacity to proceed with installing a new concrete deck. Sections were removed from selected existing piles, and a vertical load was applied to the lower pile portion, using the bridge as a counterweight. The measured pile capacities and resulting design load factors were sufficient to allow design and construction to proceed.

The final rehabilitation design upgraded the bridge into a continuous, semi-integral steel girder bridge with a composite concrete deck. Due to the site’s remote location, the precast deck panels were utilized, and specifications were developed for mixing concrete on-site for cast-in-place substructure components (abutments, pier diaphragms, pile concrete, and deck panel joints). One pier assembly was replaced with rock-socketed pipe piles due to potential scour susceptibility.

Single-lane traffic was maintained throughout construction without a detour.

The design focused on developing practical and effective renewal solutions to improve both the service life and seismic and climate change resilience of the structure, effectively resulting in an almost new structure that is expected to gain at least another 30 to 40 years of service.

Approach

- Pile Test Program: 4 piles tested to pre-determined limits to avoid failing the piles or bridge components.

- Hydrotechnical: Analysed hydraulics & scour with climate change effects to confirm the suitability of existing piles resulting in Pier 3 being replaced with rock-socketed piles. Debris loads on all piers were considered.

- Load Evaluation: Analysed various configurations (composite vs non-composite; continuous vs simply supported; semi-integral vs conventional). A composite deck with a continuous semi-integral configuration improved live load capacity & improved durability.

- Seismic: Foundations became integral with the superstructure, resulting in improved seismic performance.

- Durability: Deck joints & drains were eliminated through structural & hydraulic analysis, removing a major source of deterioration for the steel girders & piles.

- Concrete: A methodology was developed to dry-batch the concrete & add water on-site for cast-in-place components.

This required a trial mix to be performed using the same equipment to demonstrate suitability. - Traffic: Maintained 1 lane of traffic throughout construction without requiring a detour. Minimum lane widths achieved by extending existing rails out 300 mm & offsetting centreline joint between precast deck panels.

- Constructability: Precast deck minimized schedule & concrete quality risk.

- Cast-in-place substructure, so no temporary supports were required.

- Environmental: Pier 3 construction scheduled for low flow periods.

Results

- New concrete deck with durable detailing will increase the service life by 40 years.

- Bridge deck (lanes, shoulders & bridgerails) updated to current highway standards.

- Load capacity has been increased to exceed current highway standards.

- Improved resiliency to climate change (scour & debris impacts) & earthquakes.

- Maintained traffic on the existing bridge throughout construction.

- Minimized environmental impacts by performing in-stream pile testing & construction during periods of low

Service(s) Provided

Prime Consultant

Pile Testing

Assessment

Preliminary Design

Detailed Design

Construction Engineering Services

Project Team (Consultants)

GeoNorth Engineering

JMK Dumont

McElhanney

Triton Environmental

AllNorth Consultants

Project Team (Contractors)

Surespan Construction

Go back to projects in

View other projects from

Stay in touch with us

Subscribe to our mailing list!

Organization

Connect