About the Project

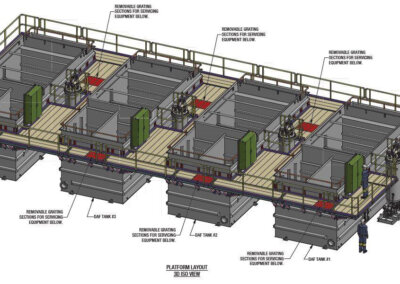

AWC was selected to provide the City of Celina with four (4), turnkey, Dissolved Air Filtration (DAF) Packages and platforms. The 4 packages were engineered, designed and fabrication in Langley, BC, and shipped to an existing water treatment plant located in Celina, Ohio, USA. Each package consisted of two flocculator chambers, a clarifier, break tank (all built as one tank for ease of installation at site) and recycle skid. The package was designed for a maximum flow of 1 MGD and required to fit within the required shipping envelope from Langley, BC to Celina, Ohio and had to meet a >200 page engineering specification.

The packages required our Process Team to identify equipment needed along with the appropriate design parameters. The mechanical designers and engineers designed the tanks and selected the final equipment, Structural Engineering designed the bracing and stiffening for the tanks and overall package. The Electrical Team designed the power and control distribution to the equipment, I&C selected the instrumentation and engineered the required controls with automation writing the program. AWC’s Production Team fabricated the tanks, the Assembly Team installed all the equipment, Electrical built the panels and installed all the cabling and the Quality Assurance team performed a Factory Acceptance Test (FAT) on the equipment prior to it being shipped to site.

Once the equipment arrived at site, the site General Contractor followed AWC’s Installation Work Package for the install. During the install, AWC’s Equipment Operators provided classroom training to the Client’s Operators and once installed, AWC’s Operators went to site to start up the equipment and complete on site training. AWC’s Operators arrived on site on for a week long activity of starting up the equipment. However, after three days, the packages were all in service exceeding the Client’s expectations with regards to ease of startup, immediate equipment performance and few deficiencies.

Approach

This project was performed during COVID which required the team to perform the engineering, design and procurement from home with very few members having previous experience working together and a number of employees new to AWC. Never, in AWC’s history, has an engineering execution model been carried out with the team working remotely and it was the first project where most of the team never even saw the final product being built in the fabrication shop!

This project required the company to adapt the way the team developed their technical deliverables and communication between team members. For projects normally executed by small close teams, it now had to be performed in a virtual environment where everyone needed to understand each others’ needs and interdependencies, and maintain an aggressive schedule (there were penalties for being late).

A detailed project schedule was set up with several “easy to achieve” gates for the team to get through. It was made clear to all what everyone was working on and how everyone was progressing. Issues were immediately identified and resolved (a culture of no sacred cows was born). A virtual team meeting was held weekly where recognitions were given to those that went the extra mile for team mates, the project updates and needs were discussed; the schedule, rolling action item log (RAIL), requests for information (RFIs), project change orders (PCNs), procurement log and quality reports reviewed.

Results

The project was a great success not only due to exceeding Client’s expectations, but also because of how well the execution team came together under difficult circumstances.

Overall effective communication, executing efficiently to meet the schedule, fostering open dialogue with no retribution for questions asked, team engagement to improve from lessons learnt and team members supporting and appreciating each other in internal project meetings all lead to the success of the project.

Service(s) Provided

– Process engineering services

– Mechanical engineering

– Structural engineering

– Piping design

– Electrical engineering and design

– Instrumentation and control engineering

– Automation services

– Welding and machine shop services

– Assembly services

– Panel shop services

– Electricians

– Quality Assurance services

– Operations services

– Supply Chain services

– Project and engineering management services

Prime Consultant

Hazen and Sawyer

Project Team (Consultants)

Osborn Engineering

Go back to projects in

View other projects from

Stay in touch with us

Subscribe to our mailing list!

Organization

Connect