About the Project

The Corra Linn Spillway Gate Replacement Project revitalized a 90-year-old spillway the Kootenay River, upgrading aging gates and hoisting equipment to meet modern safety and seismic standards at this critical facility that controls water levels for Kootenay Lake and two generating stations. Knight Piésold (KP), as the Owner’s Engineer for FortisBC, led project implementation that maintained uninterrupted operations throughout the renovation, ensuring power supply and flood control for the region despite the original design lacking provisions for gate replacement. The successful modernization not only extended the dam’s operational life but also serves as a model for upgrading similar aging, critical infrastructure across Canada.

With spillway gates and hoisting equipment that were nearing their end of life, the primary goal of the project was to modernize spillway infrastructure and improve dam safety against modern seismic standards without interfering with the many pivotal roles the facility provides for the region. This meant that work had to be completed without the ability to draw down reservoir water levels to support risk management, and gate and hoist outages had to be done in stages over seven years while adhering to strict seasonal flow requirements.

The project, which serves multiple needs and stakeholders in the region, required a Certificate of Public Convenience and Necessity (CPCN) from the BC Utilities Commission (BCUC) and compliance with the water-use/water-level orders of the International Joint Committee (IJC).

Approach

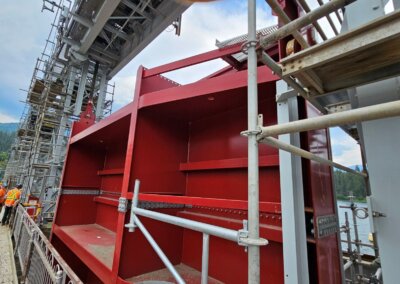

Due to the lack of traditional isolation methods on the spillway, KP led FBC through an Early Contractor Involvement phase to develop a unique construction solution to minimize operational interference and hydrologic risk while maximizing safety. A new gantry system was built, spanning all fifteen of the spillway piers, and integrated with the exiting travel mechanisms of the spillway hoists. This minimized expensive barge work and dive work when moving cofferdams or gate sections.

The project overcame several technical challenges, including managing unknown conditions of concealed components, designing multi-chamber cofferdams for variable water levels, creating safe installation procedures near active spillways, and developing alternative construction methods to reduce risk and cost. Purpose-built cofferdams and a new gantry system were developed to isolate and move the gate pieces.

This collaborative approach and innovative problem-solving allowed the team to overcome technical challenges, improve the risk profile, and optimize project costs while maintaining operational requirements and environmental commitments.

Results

The project successfully replaced all 14 gates while adhering to all water level requirements for surrounding communities, extending the dam’s operational life and ensuring continued power supply and flood control. Dam safety protection was improved to meet modern seismic standards while maintaining uninterrupted operations. The project serves as an example for critical infrastructure rehabilitation, providing valuable insights for future upgrades to aging dam infrastructure across the country.

Service(s) Provided

• Owner’s Engineer

• Early Contractor Involvement design optimization, technical specifications, and contract management

• Structural, Mechanical and Electrical design reviews

• Owner’s construction quality assurance, factory inspections, and testing monitoring

• Hydrologic modelling

• Commissioning support

Project Team (Consultants)

Magna IV Engineering

Andritz

Go back to projects in

View other projects from

Stay in touch with us

Subscribe to our mailing list!

Organization

Connect